General Information

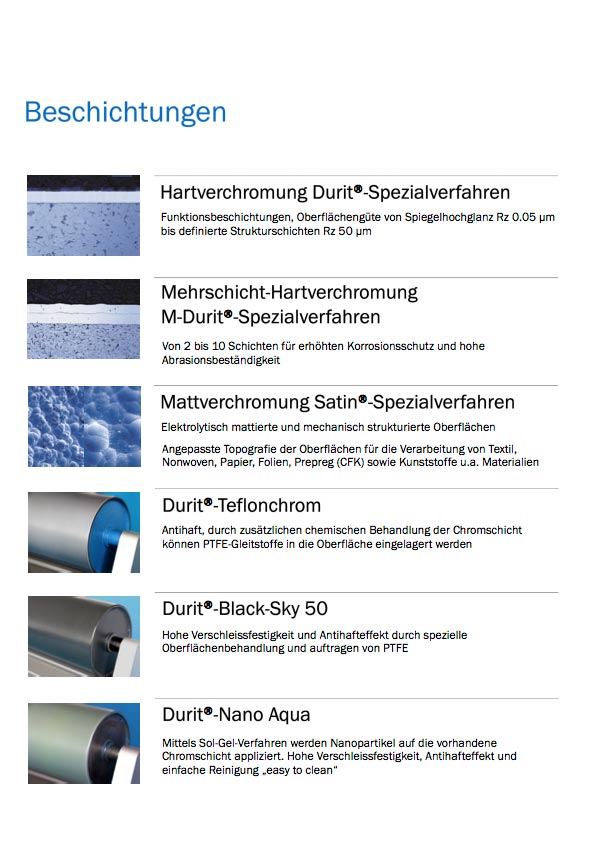

Each workpiece can be hard chrome plated either partially or fully. This requires a corresponding jig or model (current contacting, masks and anodes etc.) for each workpiece. Either a required plating thickness is applied or chrome plating is performed to a specific size. Such customised chrome plating operations can be performed reliably at plating thicknesses of max. 0.05 mm up to quality 7 (no rework necessary). Special processes ensure that a specific degree of gloss or a defined wettability can be achieved controllably and reproducibly. Likewise, surfaces with a customer-specified roughness are achieved.

Thanks to the exceedingly diverse properties of hard chrome, there are virtually no limits to the fields of application. The most important features of hard chrome platings are as follows:

- Hardness 62 – 65 HRC (750 – 1050 HV)

- Melting point 1850 – 1900 °C

- Thick platings possible (> 1 mm)

- High wear resistance

- Good coefficient of friction

- Good corrosion resistance; min. 0.08 mm plating thickness in the case of multi-plating processes

- Poor wettability

- Definable surfaces (from very fine to rough, from matt to high-gloss)

- Can be remachined mechanically (grinding and polishing etc.)

- Workpieces can be reconditioned several times

- Low processing temperature (geometrically precise parts are not warped)

- Very small to very large workpieces can be plated